Quality Control Programme

Our QC Process

Strictly According to ISO9001:2015 System, ensure the professional reliability of our service and quality.

1st Level Inspection:External Visual Inspection

Appearance test refers to confirming the number of chips received, inner packaging, Humidity indicator, Desiccant requirements and appropriate outer packaging.

Second, the appearance inspection of a single chip, mainly include: Chip typing, years, Country of origin, Whether to recoat, Pin status, Are there any re-sand marks, Unknown residue, factorylogos position.

2nd Level Inspection: Quality Inspection

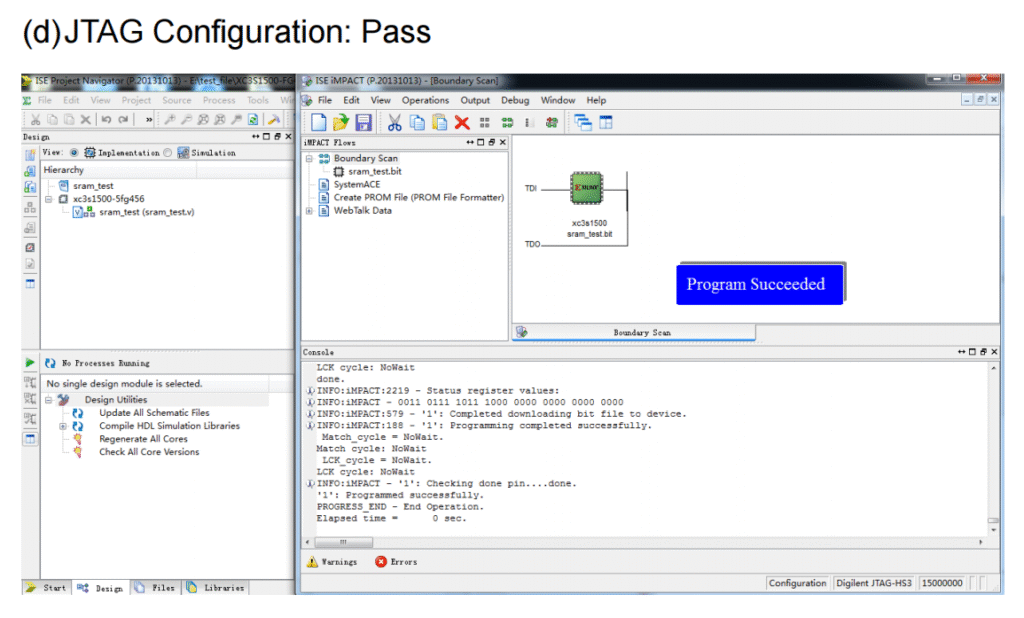

Programming

We use support to detect 208 EachIC Produced by the manufacturer 47000 Species ICModel programming device.

Provided include: EPROM, Parallel and serial EEPROM, FPGA, Configure serialPROM, Flash memory, BPROM, NOVRAM, SPLD, CPLD, EPLD, Microcontroller, MCUAnd standard logic device testing.

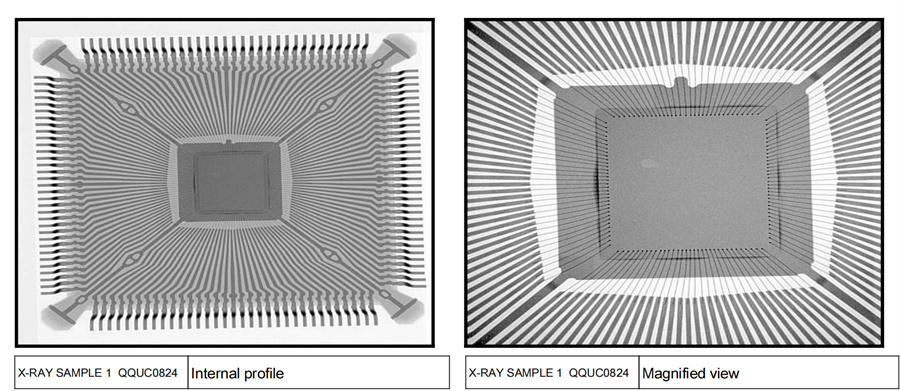

X-Ray

X-rayTesting is a real-time non-destructive analysis to check the hardware components inside the component, Mainly check the lead frame of the chip, Wafer size, Gold wire binding diagram, ESDD amage and holes, Customers can provide usable samples or previous purchases for comparison check.

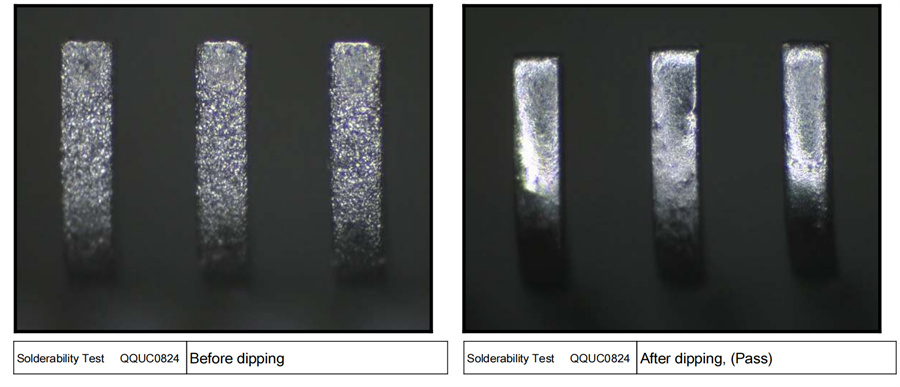

Soderability Test

The test standard for solderability test is J-STD-002B, This test mainly tests whether the soldering ability of the chip pins is up to standard.

Quality is always our main concern

Technically, we give ourselves more challenges.

Implementation, we give ourselves the most stringent requirements.

We are committed to providing customers with the industry’s highest quality, standard electronic components, products to directly meet the customer’s production needs.

We have strict quality control system throughout every process to ensure the consistency of quality with the original factory, to ensure zero-defect quality management of products.